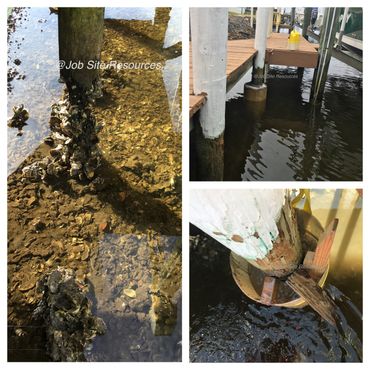

Job Site Resources, LLC (aka THE PILE DOCTOR) provides alternative Pile Repair options to the high expense of driving new piles. Whether your pilings are deteriorated and in need of repair, or you are looking to maintain and prevent future deterioration, Job Site Resources is here to help. Call today for a FREE ESTIMATE

484-955-0791.

*Servicing New Jersey and New York shorelines

Pile Repair & Rehabilitation

FRP JACKETS

Protect and save your assets stabilizing and rehabbing existing piles. FRP jackets can be wrapped around deteriorated piles to create an impervious layer of high confining pressure. The annular space is filled with a high strength, advanced marine grade epoxy fill that penetrates all voids and cracks in the pile. This provides a much stronger and stable pile which is resistant to the contact harsh marine environment. Whether rehabilitating one pile, or many piles underneath an entire structure, our services offer total care solutions.

HDPE Wraps

HDPE Wraps will protect your pilings from wood borrowing insects and splash zone areas. These wraps are made of a High Density Polyethylene UV Resistant Material that is .030" thick and is available in both 36" and 60" widths. The 60" HDPE Wrap works well in most shallow water applications whereas the 36" HDPE Wrap works well in deeper waters. These durable HDPE Wraps provide years of protection and makes for an attractive appearance on your wood pilings. HDPE Wraps are best utilized on existing piles that are in good structural condition with little to no breakdown. The purpose of these HDPE Wraps is for preventative measures, to help extend the life of already healthy, existing pilings.

Bulkhead Repair & Rehabilitation

Our method of repair and/or rehabilitation of your bulkhead includes the steps of installing a plurality of tiebacks and/or heavy duty manaray anchors attached directly to the existing bulkhead, and a new bulkhead facing is connected to the existing bulkhead which has been supported by the anchors. An alternate method may include installing several vertical piles at horizontally spaced locations in front of, i.e. on the water side of, the existing bulkhead; connecting the vertical piles to the existing bulkhead; installing anchors through the existing bulkhead and into the land behind the existing bulkheads; and connecting the tiebacks to the vertical piles. In situations where use of piles and anchors alone are not sufficient to rehabilitate the bulkhead, a new bulkhead facing is installed in front of the existing bulkhead. It is then connected to and supported by the piles and anchor supports by the existing bulkhead.

Pile & Bulkhead Repair Photos

Copyright © 2022 Job Site Resources - All Rights Reserved.

Powered by GoDaddy